HDPE Plastic Solar Floats

The high density polyethylene (HDPE)-based float is the most common floating solar technology used today. HDPE is polymer manufactured through a blow moulding process and is resistant to UV radiation and corrosion, and has a high tensile strength. HDPE solar floats can be easily installed, saves cost and it has a long life of more than 15 years. While many designs have emerged in the market for this float type, most include the installation of solar panels directly on the HDPE floating platform, with a maintenance float provided alongside the main float.

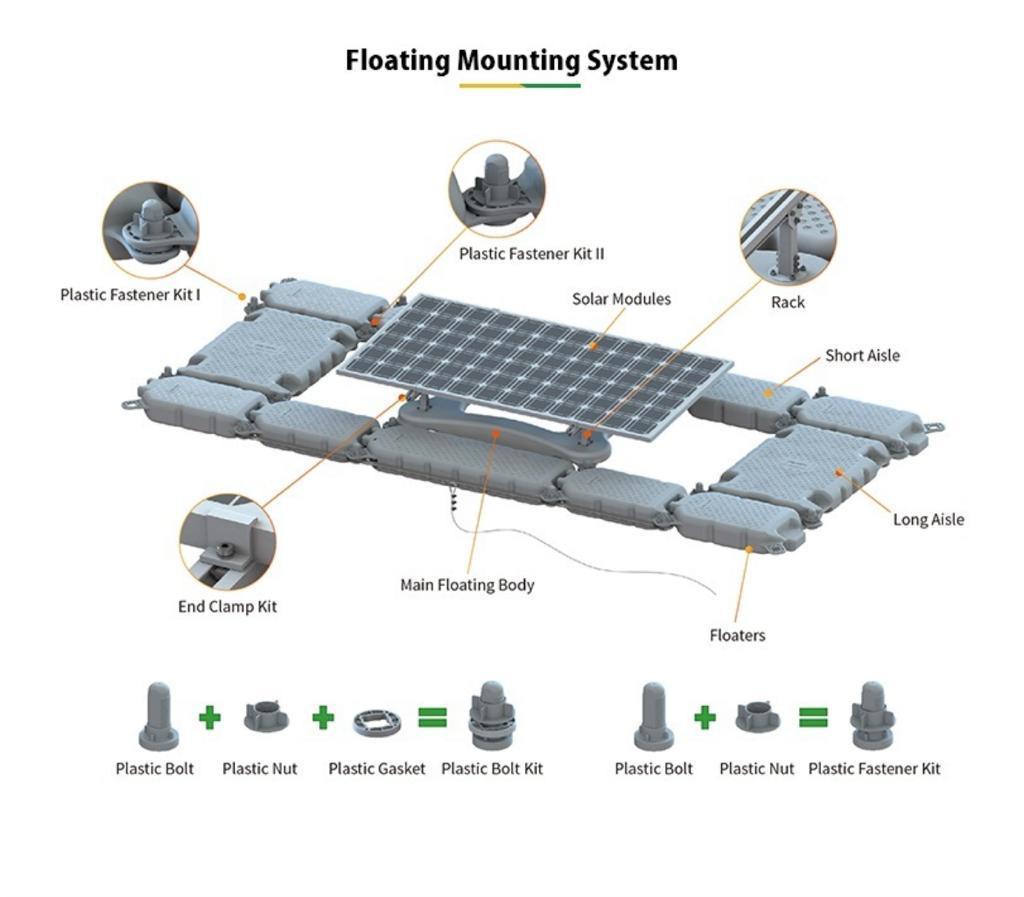

Different Types Of Floats are used in the installation of floating solar project. HDPE solar floating mount consists of main floating mounting body, outer aisle, different long and short aisles, rack, spreader bar, fixing system, etc.

We manufacture the above floats on large extrusion blow molding machines with quality molds designed as per the project requirement.

Different size die core and platen are required for each size of the float. The ESCR of the material used should be high to withstand external environment condition.